eResin-Flex

High elongation at break, good elasticity, tear resistance, tensile, bending and compression, quick rebound, a certain wear resistance. Relative high success rate of release, easy to print.The parts are soft and elastic, resistant to bending.Can be used on product models that require softness.

- * Description:

-

Description

High elongation at break, good elasticity, tear resistance, tensile, bending and compression, quick rebound, a certain wear resistance. Relative high success rate of release, easy to print.The parts are soft and elastic, resistant to bending.Can be used on product models that require softness.

Sellingpoint

Good elasticity

Tear resistance

Bending resistant

High toughness

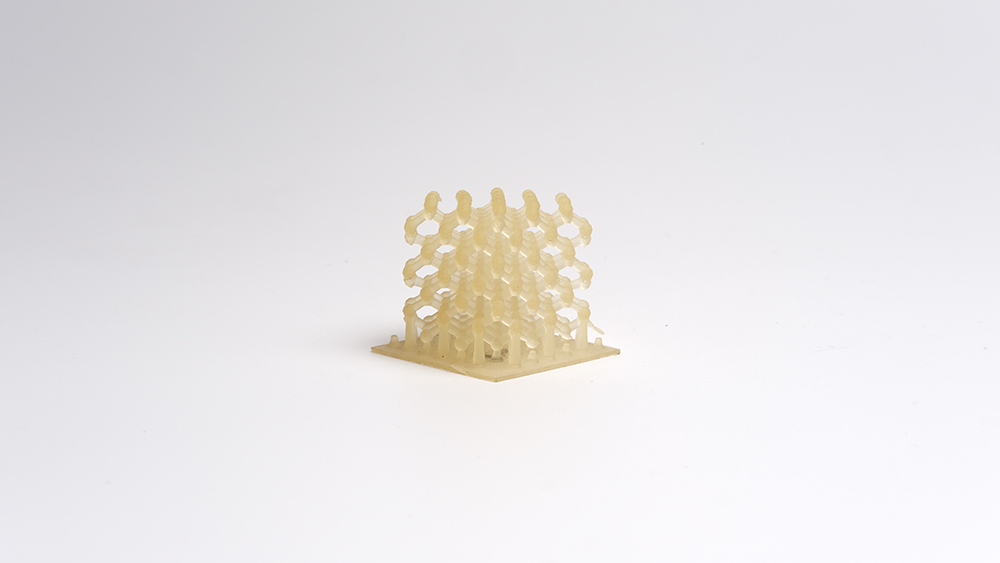

- * Application

- * Print model

-

| 3D PRINTING PHOTOPOLYMER RESIN Properties Table | |

|---|---|

| 3D PRINTING PHOTOPOLYMER RESIN | eResin-Flex |

| Viscosity(mPa·s) | 600-1400 |

| Density(g/cm3) | 1.02-1.05 |

| Tensile Strength(MPa) | 4-10 |

| Elongation at Break(%) | 100-350 |

| Flexural Strength(MPa) | / |

| Impact Strength(J/m) | / |

| Tearing Strength(GPa) | 8-30 |

| Heat Distortion Temp(℃) | / |

| Hardness(Shore D) | 60-90A |

| Grades (out of 10) | |

| Strength(S) | 2 |

| Toughness(F) | 10 |

| Forming(P) | 4 |

| Accuracy(S) | 6 |

| Speed (A) | 4 |

| Recommended printing parameters | |||

| Settings | Machine Type | ||

| Low Light Intensity | Medium Light Intensity | High Light Intensity (Monochrome LCD Screen) | |

| Representative Machine | AnyCubic Photon | eSUN LCD 3.0 Nova Bene 4 Creality LD-002R |

Anycubic MONO X ELEGOO Saturn Phrozen Sonic Mini |

| Exposure Time/s | 8-10 | 5-6 | Not recommended |

| Bottom Layer Count | 3-5 | ||

| Bottom Exposure Time | 40-70 | 30-40 | Not recommended |

| Lifting Distance/mm | 5.5&6-inch screen:5-6 or Higher ; 8.9&13.3-inch screen:8-12 or Higher | ||

| Lift Speed/mm·min-1 | 50 | 50 | Not recommended |

| Retract Speed/mm·min-1 | 100 | ||

1.Shake well before printing

2. Slice setting:

Stronger support: Avoild break with main body

Denser support:Avoid deformation dislocation

3.Printing data

Higher lifting distance: full film realse

Lifting distance:≥6mm

Slowing down Lifting speed: avoid breaking

Lifting speed: ≤60mm/min

Control leveling time: full leveling

Light off delay≥6s

4.Post Curing

Properly control the post curing time, the longer the exposure time, the higher the hardness of the curing material, the worse the flexibility, and the heavier the yellowing

To ensure good flexibility of the material and avoid hardening problems caused by post-curing, it is recommended to clean the printed parts after printing instead of post-curing

The surface sticky hand condition will be gradually improved under the indoor weak light condition. Avoid strong light exposure for later storage

-

REACH

REACH -

ROHS

ROHS -

TDS

TDS