eSUN green filament — eBamboo!

2017/09/06

eSUN green filament — eBamboo!

Wood-plastic composites(WPCs) arecomposite materialsmade ofwood fiber/wood flourand thermoplastic(s) (includesPE,PP,PVC etc.).

Wood plastic composites is an absolute green material widely used in buildings, furniture, landscape design, wood plastic toys, etc.

Regarding of our environmental issues, wood plastic composites also helps to relieve the shortage of forest resources and waste pollution. The “green” concept makes wood plastic composites a welcomed material in 3D print industry. eSUN now puts out wood plastic composites—eBamboo,a filament composited with polymer resinmatrixand the main component is preprocessed plant fiber or powder.

About eBamboo

- eBamboo has a matte, frosted texture, good melt fluidity, no stripping and can print smoothly;

- It has wood texture and wood aroma;

- Renewable, pest control, long life, very green and can be sprayed.

- It’s suggested not to pause for too long and remove prints from the nozzle as soon as possible, or the wood powder will expand and burn.

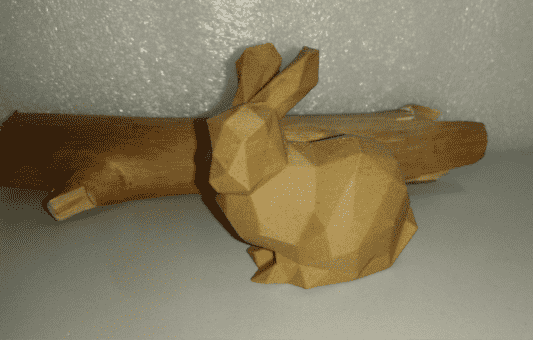

Comparison: ebamboo (left, bamboo powder) and wood (right, stripping)

PerformanceIndicators

| Performance | Testing method | Unit | eBamboo |

| density | ASTM D 792 | g/cm3 | 1.2 |

| Melt index(220℃/10kg) | ASTM D 1238 | g/10min | 10-18 |

| Tensile strength | ASTM D 638 | Mpa | 28 |

| Elongation at break | ASTM D 638 | % | 3-7 |

| Bending strength | ASTM D 790 | Mpa | 35 |

| Bending modulus | ASTM D 790 | Mpa | 2000 |

| Izod Notch impact strength | ASTM D 256 | KJ/m2 | 10 |

| Distortion temperature(0.46Mpa) | ASTM D 648 | ℃ | 48 |

Printing parameters

- Best print temperature: 200-220℃

- Bed temperature: 25-70℃

- Feed rate: 20-90mm/s

- Idling speed: 90-150mm/s

Printing notices

1. Leveling printing plate before starting;

2. Heat the hot bed to 25~70℃ before printing, paste transparent golden polyimide high temperature resistance tape to the surface and keep it clean;

3. Keep a optimumdistancebetween nozzle and plate (which allows you to paint out a flat line while moving your nozzles; if too far the line will print out extremely thin lines and too close will be hard to let filament out);

4. A lower filling rate can remit shrinkage crack during printing process;

5. Nozzlediametershould be bigger than layer thickness. Tryparameter like 0.2, 0.25, and 0.3;

6. Better keep cooling fan off when printing and print in a closed area. Puttingflapper around printer also helps to keepconstant temperature environment.

PS: eASA has higher filling rate, please try to avoid drag or twine regarding of its brittleness; it’s also suggested to dry the filaments before using because it can be affected easily with damp once open.

Application area

Because eBamboo is renewable, pest control, long life, very green and can be sprayed, it can be applied in building materials, automobile industry, package and transport, storaging, furnishing and other areas.